Steve Payne

“The One Series” of ICFs that you need to know about

Canadian Contractor BasementNUDURA's One Series combines traditional forming methods and Insulated Concrete Form technology, together

The following is a sponsored post courtesy of NUDURA.

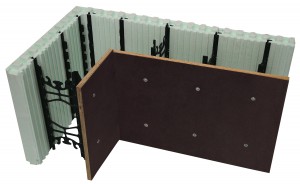

The One Series by NUDURA is the industry’s only multi-link form offering builders and architects unmatched versatility for projects designed using ICFs. At the core of this innovative line is DURA MULTILINK TechnologyTM, a newly designed web that offers users the ability to create a wide variety of custom multi-sided form combinations for a variety of building types from commercial to residential. The One Series also features DURAMAX TechnologyTM, the industry’s largest standard form on the market, 8 feet (2.4m) long by 18 inches (457mm) high placing 12 sq. ft. (1.11m2) of wall area in one building step.

The One Series by NUDURA is the industry’s only multi-link form offering builders and architects unmatched versatility for projects designed using ICFs. At the core of this innovative line is DURA MULTILINK TechnologyTM, a newly designed web that offers users the ability to create a wide variety of custom multi-sided form combinations for a variety of building types from commercial to residential. The One Series also features DURAMAX TechnologyTM, the industry’s largest standard form on the market, 8 feet (2.4m) long by 18 inches (457mm) high placing 12 sq. ft. (1.11m2) of wall area in one building step.

The One Series will offer users the ability to reduce labor by not having to strip foam for elevator shafts, stairwells and other areas that do not require foam. The One Series gives architects the ability to have more versatility with design for multi-storey, educational and commercial warehouses. For home builders, the One Series is ideal for pools and anywhere only one side of foam is needed. Transition between concrete and foam is seamless, the unique design allows concrete to meet with the outside edge of a NUDURA foam panel. The DURA MULTILINK TechnologyTM web, uses smaller attachment points that have been created to alleviate webs being visible in the concrete side of the wall. This innovative design features only two small connection points per web that are easily covered over and hidden. The end result is a smooth interior or exterior surface.

How does it work? The One Series combines traditional forming methods and Insulated Concrete Form technology together. NUDURA supplies all of the materials necessary to complete the multi-link form, from the webs, form ply, screws and specially designed jig to make assembly easy and fast. The form ply pieces are pre drilled which eliminates the need for onsite drilling, installers simply assemble to the desired form combination quickly and easily. Combine this with NUDURA’s innovative existing ICF panel system, custom form combinations and transitions between 90°, 45° are easily done. Once the job is completed all of the form ply panels can be stripped, cleaned and reused for the next job, eliminating waste and further cost.

How does it work? The One Series combines traditional forming methods and Insulated Concrete Form technology together. NUDURA supplies all of the materials necessary to complete the multi-link form, from the webs, form ply, screws and specially designed jig to make assembly easy and fast. The form ply pieces are pre drilled which eliminates the need for onsite drilling, installers simply assemble to the desired form combination quickly and easily. Combine this with NUDURA’s innovative existing ICF panel system, custom form combinations and transitions between 90°, 45° are easily done. Once the job is completed all of the form ply panels can be stripped, cleaned and reused for the next job, eliminating waste and further cost.

Learn more about the NUDURA One Series at a training class near you. Visit www.nudura.com/training or call 866.468.6299.

Advertisement

Print this page

I will use the One Series Nudura to make a carport below grade, using the insulation only on the exterior and the plywood on the interior as a finish. No point having insulation on the interior and I save 2+ inches of space.

Since engineering is required and I have to pour a concrete wall, I will do it with ICF as usual as no other wall construction is able to withstand the backfill. Form rentals here on an island are expensive to get and return. So ICF works the best. The other thing I ask the engineer to do is reduce the concrete in the form from 8″ to 6″ thereby reducing another 25% since concrete is $300 per meter.

Bill that is wonderful to hear!

Glad the One Series will work out so well for your project! As a note – the plywood can be removed if you wish to have a concrete finish (or require non-combustible material in any sections), but you can certainly leave it as you have planned.

If you are on Twitter, follow us and share photos, we would love to see the project take form. @NUDURAICF is our Twitter handle.