John Bleasby

FlexVolt & brushless motors: DeWalt’s giant leap towards the cordless job site

Canadian ContractorPowerful, intuitive batteries and high efficiency motors will soon deliver the contractors’ Holy Grail

A cordless job site? Transforming even power –hungry 110V corded drills, grinders and saws into fully portable tools? The combination of brushless motors across the DeWalt line in combination with new patented FlexVolt battery technology is about to make the ‘Cordless Job Site’ a reality. Surely this is the Holy Grail for contractors!

Brushless motors run cooler and run longer, and therefore more efficiently

List the many advantages of brushless motors over brushed motors to most people and heads will nod knowingly in agreement. It’s like hearing about the latest smart phone technology: Yes, we recognise what’s better, but really don’t understand the details.

An internal look at brushless and brushed motors. Note the brushless circuitry (green) on the left and the friction from brushes (red) on the right

In a nutshell, brushless motors are superior because they are….brushless!

“The first thing people gravitate towards when it comes to brushless motors is the increase in durability,” says Ward Smith, Group Product Manager for DeWalt USA. “With brushed motors, there is a physical connection to the copper in the motor.” That connection causes friction, and friction causes heat. Heat is not a good thing when a tool is used either continuously or under heavy load. “With any kind of moving part, you want to keep it cool,” says Smith. Friction is another way of saying ‘efficiency and energy loss’, meaning the tool user is getting less ‘bang’ for their energy ‘buck’. Bottom line; brushless motors can run longer and harder with less friction, less heat, and therefore with less energy loss.

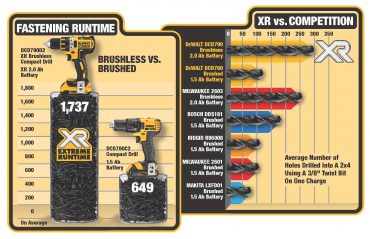

DeWalt compares the efficiency and run time of its brushless motors tools against its own brushed motor tools, and against competitors’ brushless tools.

More work per charge? Advantage brushless!

This may not seem important when plugged into a wall socket or generator, but put those benefits of low friction into the world of cordless tools and the advantages are obvious; “More work per charge,” says Smith. In a given battery, no matter what voltage, the more actual work you can get out of it between charges, the more efficient you are and the faster the job gets done.

Because of their internal electronics, brushless motors are also ‘smarter’, meaning they can sense what level of power they need to draw to do the job. For example, a saw will sense the level of power required for cutting a piece of 5/8” strapping versus a 4”x4” post. Result? Efficient use of power.

The new DeWalt FlexVolt mitre saw has the option of being powered by pairing the 60V FlexVolt battery system (120V total), or plugged into the wall

Brushless motors means tool design options

Brushless motors are also more compact than their brushed predecessors, giving tool designers a couple of options; they can make tools more compact for the same power, or they can make the tool more powerful for the same size. It comes down to the tool and its application. Some tools, like an impact driver, are expected to be smaller, explains Smith. However, in a circular or a reciprocating saw, designers can offer a lot more power in the same size unit.

However, there’s a cost to the advanced electronics of a brushless motor. It’s not just their ‘smartness’ but also added features like advanced control switches and LED lights. “There’s more software,” explains Smith. “A brushed tool is mechanical. A brushless tool is both mechanical and electronic.” Therefore, brushless cordless tools will remain premium products as long as there are budget-conscious home handymen content with lower-priced brushed power tools.

DEWALT’s patented FlexVolt intuitively switches between 20V parallel power for smaller hand tools and 60V series for the largest of work site tools

FlexVolt: DeWalt’s great leap forward

Combine brushless motors with DeWalt’s patented new FlexVolt technology coming this fall, and the Cordless Job Site is in sight. All battery packs amongst the major tool manufacturers have progressed from the early days of nickel cadmium to today’s advanced lithium chemistry. But nothing to date equals what DeWalt has done.

FlexVolt 60V batteries are not merely powerful but also uniquely adaptable. How so? They are ‘backwards compatible’, meaning they will run any DeWalt tool from a 20V drill up to the new full-size 120V cordless table and mitre saws (when paired) by intuitively switching from series to parallel, based on the tool being used. “The user doesn’t have to do anything other than take the battery and in out of the tools,” says Smith. That added flexibility means corded performance in a totally cordless environment, and allows Smith to add, “I would argue that we now have the largest range of cordless, brushless tools in terms of applications.”

While Smith acknowledges an inherent reluctance to use a larger battery in a size-sensitive tool like an impact driver, he says users of 20V tools like reciprocating saws and drills will appreciate the increased run time offered by the larger 60V “gas tank”. DeWalt designers have been diligent about retaining enhanced ergonomics in their cordless product line, no matter the battery pack size. “Users will notice the larger size and increased weight, but still comment favourably on the ‘good feel’”, says Smith.

DeWalt’s one-two punch!

The implications of the FlexVolt system and brushless motors are huge on sites where standard power delivered through live wires or generators is unavailable, unsafe, or impractical. FlexVolt technology combined with brushless motors’ many advantages makes it possible to run tools longer, harder and most importantly, cooler. All without cords!

DeWalt FlexVolt technology and their expanded line of brushless cordless tools will be available at Canadian retailers this fall.

follow John on Twitter

@john_bleasby

Leave a Reply