John Bleasby

The case for electrical radiant floor heating

Canadian ContractorOccupant comfort, energy savings and customized heating zones are compelling arguments

Two presentations at the Building Show in Toronto last December highlighted reasons why more new homes are choosing in-floor electrical radiant heating systems. John Bleasby summarizes the pitch made by two industry experts.

Silent. No moving parts. Maintenance free. Reduced capital cost. Reduced airborne dust and contaminants. No future replacement costs. With promises like that, it would be hard not be a little excited by in-floor, electrical radiant heating systems. However, Rick Fraij, founder of Petra Building Solutions Inc. based in Gatineau QC, believes the most compelling reason to choose in-floor radiant heat has to do with occupant comfort.

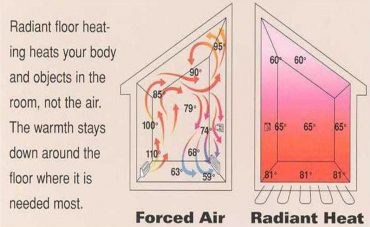

graphic: Petra Building Solutions

The warm object, warm body argument

Fraij explains that radiant heat warms the objects in the room, not the air. “The warmth stays near the floor where it is needed most,” he says. On the other hand, forced air heat moves all over a room’s volume, changing temperature as it moves. The heat rises to the ceiling, leaving temperatures cooler at the floor lower, resulting in a lack of occupant comfort and wasting energy. Baseboard heaters and radiators do much the same thing, Fraij says, creating convection currents that collect heat at the ceiling, leaving floors cold and rooms uncomfortable.

On the other hand, radiant heat moves from the surface of warm objects to the surfaces of a cooler ones in the form of electromagnetic waves where it is absorbed, says Rob Dyba, Residential Sales Manager with NVent Thermal Building Solutions of Richmond, BC.. The body absorbs that heat in much the same way.

In-floor radiant heat systems are out of sight

The components of an electrical radiant heating system are simple to understand. First, there is the heat source (cables or electrical mats), then typically a thermal mass over top (thin set, or self-leveling concrete), and finally a finished floor covering (tile, stone, vinyl laminate or engineered flooring). The system is invisible.

Comfort goes well beyond a whole-house heat approach, however. Today’s in-floor systems allow occupants to choose which room and which zone in each room requires heat. Not only that, using probes that are floor-sensing, not ambient sensing, thermostat controls can be programmed for time-of-day and day-of-week. Furthermore, new technology now offers remote wireless smart home connections for whole-home energy control that can include the radiant heat floor system.

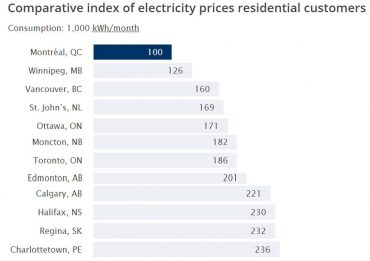

The economy of electric heat varies with electricity costs across the country

(graphic: Quebec Hydro 2018)

Reduced electrical costs? Yes, maybe.

Fraij suggests that this high level of precision programming can reduce electrical energy costs between 30 and 60 per cent versus traditional whole-house electrical heating systems, and even compete with other energy sources. Dyba quantifies this, saying that, “12 watts equates to 41 BTU’s across an entire floor surface.”

However, since electricity rates vary so much from province to province across Canada, it is important to investigate any claims of reduced energy consumption versus alternate energy sources before jumping to firm conclusions. In any case, no matter what the local rates, these new, programmable in-floor heat systems are less expensive to run than their always-on electrical heat counterparts.

Important choices for heating cable inlays

Radiant floor panels come in combinations of mats, membranes, cables and meshes with costs ranging from $5 to $15 per square foot. They can be installed under engineered wood floors (with strict installation guidelines issued by the flooring manufacturer), tile, stone, and concrete. Mats are often available in standard rectangular shapes, however some systems can be customized for any floor design.

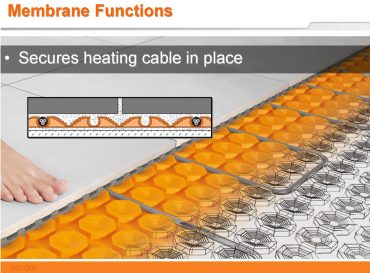

Cracking of tiles and stone floor coverings is usually the result of stress movement

(graphic: NVent Thermal Building Solutions)

Finished floor surfaces are limited

There are restrictions resulting from the selection of an electrical in-floor heating system. The finished floor surface is limited to hard surfaces like tile, stone, possibly vinyl and engineered wood, and concrete. Natural wood floors are not normally recommended due to dimensional stability issues. Due to their relatively high insulation qualities, cork and carpet are not good choices either. In any case, more homeowners are choosing hard surfaces due to their ease of maintenance and hypoallergenic qualities. If those surfaces are unheated, they can be quite cold under foot. That’s why in-floor heating can make good sense.

Serious installation considerations over the long term

Traditionally, an electrical in-floor heating system consist of cables hand-laid back and forth across the floor, then covered in a thin, self-levelling concrete mix. “Floor warming cables should be installed only in areas there is no permanent fixture or object above the cables,” adds Fraij, such as toilets, cabinets and vanities.

However, there can be problems associated with an installation using a substrate, principally the cracking of the tiles or grout. Tile and grout cracking results from tension, compression and shear, says Dyba. For example, bonding a tile directly to a solid substrate “transmits stresses occurring in the substrate directly to the tile.” This is a problem because substrates, either wood, OSB ,or concrete (self-levelling or slab), can move or dimensionally shift at different rates than the tile itself. Changes in thermal expansion (exaggerated due to the heating cables), moisture and loading, can impact each layer at different rates, resulting in tile and grout cracking. The answer, according to Dyba, are uncoupled membrane systems like the Ditra-Heat-E systems, which address many of these by securing the cables in place while neutralizing the stresses between the substrate underneath and the tile floor covering above.

Uncoupled membranes combine secure and precise wiring placement with a base for the floor substrate

Uncoupled membranes address two other issues surrounding installation. They can be customized to avoid permanent fixtures and deliver heat only where required. They also reduce floor assembly thickness transitions between heated and non-heated floor surfaces which otherwise can result in a threshold height change. This is because, in the first instance, the uncoupled membranes eliminate the traditional self-levelling material used to encapsulate the heating cable. Secondly, within an entire room with heated and non-heated sections, these flexible membranes can cover the entire floor with cables only running in those areas requiring heat.

Don’t forget the HVAC

While in-floor systems of all types are becoming more popular in today’s modern, tight building envelopes, it is important to point out that Internal Air Quality (IAQ) is vitally important. In fact, with heating systems that do not rely on a forced air system’s inherent air recirculation characteristics, it could be argued that the design of a home’s HVAC system becomes even more vitally important.

Got feedback? Make your opinion count by using the comment section below,

or by sending an email to:

JBleasby@canadiancontractor.ca

Follow John on Instagram and on Twitter for notifications about his latest posts

Leave a Reply