By Grant Walkin

Vapour Barrier or Vapour Retarder? You need to understand the difference

Canadian ContractorExposing important myths and misconceptions that affect building integrity

Canadian Contractor is pleased to publish the third in a series of articles by Grant Walkin, a building envelope specialist, focusing on the science behind today’s energy-efficient homes.

There appears to be confusion within the building industry between the terms vapour barrier (VB) and vapour retarder (VR). Let’s clarify the differences. The term vapour barrier should be reserved to referencing a barrier that essentially does not allow water vapour to pass, and is designated as vapour impermeable. In contrast, a vapour retarder should be used to describe a barrier that has some level of vapour permeance. Understanding the difference between these terms is critical knowledge for building designers and contractors. Equally important is knowing the permeance of the given material.

A sneak peak at vapour retardant barriers

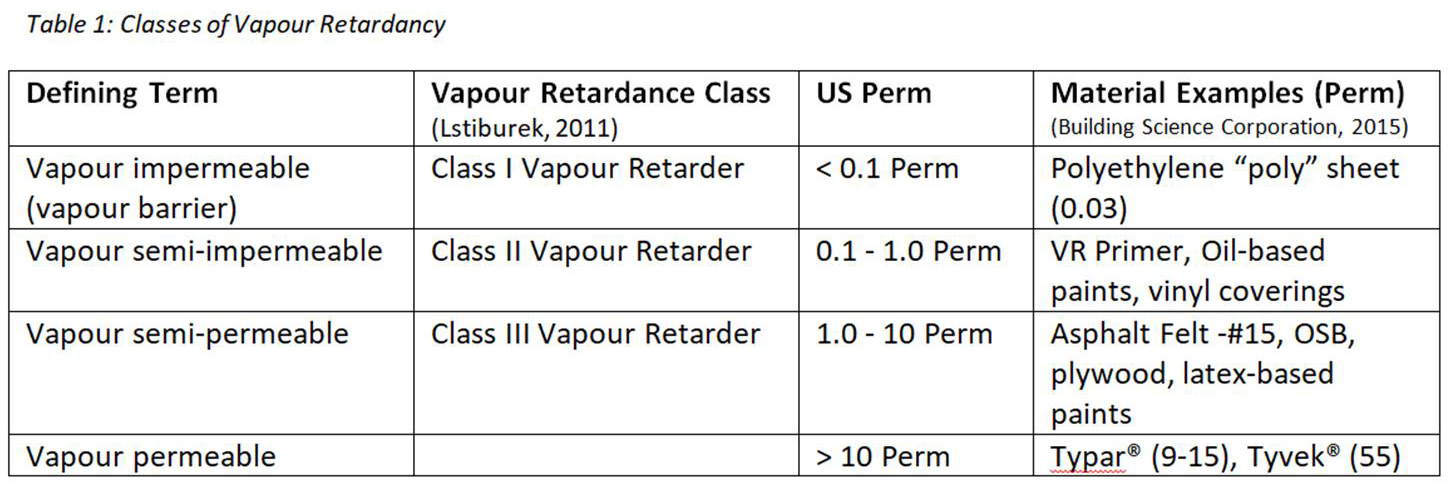

Joseph Lstiburek, a renowned building scientist and principal of Building Science Corporation, expanded on the Canadian General Standards Board (CSGB) approach by categorizing the water vapour permeance of vapour retarders in Table 1 below; where a perm is a unit of measurement usually reserved for water vapour permeance (1 US Perm = 0.66 SI Perm = 57.2 ng/(s m2 Pa)). Lstiburek designated that a vapour barrier is a Class I vapour retarder (Lstiburek, 2011).

In order to demand higher performance in buildings by combating air leakage and vapour diffusion (the movement of water vapour through a material), building codes in the US and Canada adopted the requirement for buildings to have a vapour barrier, for which they designate as a membrane that has perm rating less than 1.0 perm (Note that this membrane would be classified as a Class II vapour semi-impermeable retarder or less, as defined by Table 1 above).

More often than not, this is satisfied by means of a polyethylene “poly” sheet, i.e. a plastic impermeable vapour (and air) barrier, within the wall. Notice the permeance of poly as shown in Table 1 (0.03 Perm) is well below the required US Perm of 1 required by code.

Installing the wrong barrier can result in building failure

In Canada and northern U.S. states, where heating dominates over cooling, the vapour retarder is installed on the warm side – typically directly behind the drywall. The location of the vapour retarder prevents the warm and relatively humid air to travel into the wall where it may condense.

Building scientists agree that the use of vapour impermeable barriers are rarely necessary and in fact can be a poor strategy in all except the coldest climates such as northern Canada and Alaska. This is because the use of vapour impermeable barriers has two significant flaws. First, the vapour impermeable barrier is on the wrong side during the summer months in air-conditioned buildings — and today most buildings are air conditioned.

Second, construction itself is not perfect, and neither is the installation of a vapour barrier. While these barriers need to be continuous*, in reality there are always going to be some unintentional holes through the vapour barrier. This could occur perhaps at joints, but more typically it’s where trades such as electricians have punched a hole through the barrier and was covered up before it was noticed and repaired. The problem is that this results in a concentration of humid air flowing through that hole, while the envelope is limited to dry to only the exterior (if a vapour barrier is installed on the inside). Buildings should be constructed to be robust so that when they do suffer a localized failure, they can recover. The fact is, at some point, somewhere, your building assembly will fail — something as simple as failed sealant at a window.

*Although vapour barriers are not critical to be continuous, it is critical for air barriers to be continuous. Typically, in residential construction the poly vapour barrier also acts as the air barrier.

The solution

It’s quite simple — don’t use vapour impermeable barriers, i.e. vapour retarders with a U.S. perm rating less than 0.1 perm. Instead, use the most permeable vapour retarder that works with the building envelope assembly. Typically vapour impermeable barriers can be avoided completely in all building types except those with very high humidity levels, such as indoor pools and spas, and sometimes those in extreme cold regions.

“Smart” moisture management barriers like CertainTeed’s Membrain (TM) prevent moisture being trapped within the building envelope structure

Some things to note. It is important that the vapour permeance of building materials within the assembly are installed so that the lowest permeability rating material is installed on the interior side, gradually increasing as you move through the building assembly towards the exterior (in heating dominated climates). If a vapour impermeable barrier is required, then only install one – this is critical. This includes low vapour permeable building materials like rigid insulation, or spray foam. Do not create a vapour sandwich with these low permeance membranes and materials by placing them on the outside of a building with poly on the inside. If you do, you risk setting the building up for failure by creating something which building scientists refer to as a vapour sandwich — where the wall cavity cannot dry if when breached with liquid water or water vapour.

A myth exposed: poly is not the required ‘standard’

So why do impermeable vapour impermeable barriers, such as poly, continue to be installed, almost as the standard? The Ontario Building Code (OBC) requires the installation of a “vapour barrier”, such as a polyethylene sheet, stating under Part 9.25.4.2 that “Vapour barriers shall have a permeance not greater than 60 ng/(Pa s m2)”. This equates to approximately ~1 US perm. As mentioned above, note that the OBC (including national building codes) refers to a barrier with less than 1 US perm as a “vapour barrier”. However, based on Lstiburek’s Table, the reference to “vapour barriers” should be exclusively reserved when referring to “vapour impermeable barriers” (ie. those with less than 0.1 perm). In the OBC, it is also written that any other material other than polyethylene shall conform to “Vapour Barrier, Sheet, Excluding Polyethylene, for Use in Building Construction.” This suggests to readers that poly (polyethylene) is the standard, when realistically poly should be left exclusively for specific conditions where high vapour diffusion is a design concern. This may help explain the confusion of vapour barriers and retarders, and more importantly, why poly seems to be the standard.

Alternatives that satisfy code

As per Table 1, some acceptable options that satisfy code, based on location, include vapour retardance paint with an air sealed drywall approach, or a “smart” vapour retarder. The permeability of smart vapour retarders change with humidity — typically from one perm or less when the cavity is dry, to greater than 10 perms when the cavity is moist. This promotes drying within the wall if it becomes wet. These are good alternative options, especially for buildings with exterior insulation (remember vapour sandwiches?). For additional vapour retarder options and a list of vapour permeability of commonly used materials, refer to the data formulated by Building Science Corporation – Info-500: Building Materials Property Table.

It is important however that the final selection of a vapour retarder as well as the placement of materials within a building assembly be completed by a building professional with a good understanding of building sciences. A contractor who says, “I’ve built it this way for 30 years” is not sufficient proof of their building science understanding.

Which climate zones, and which requirements?

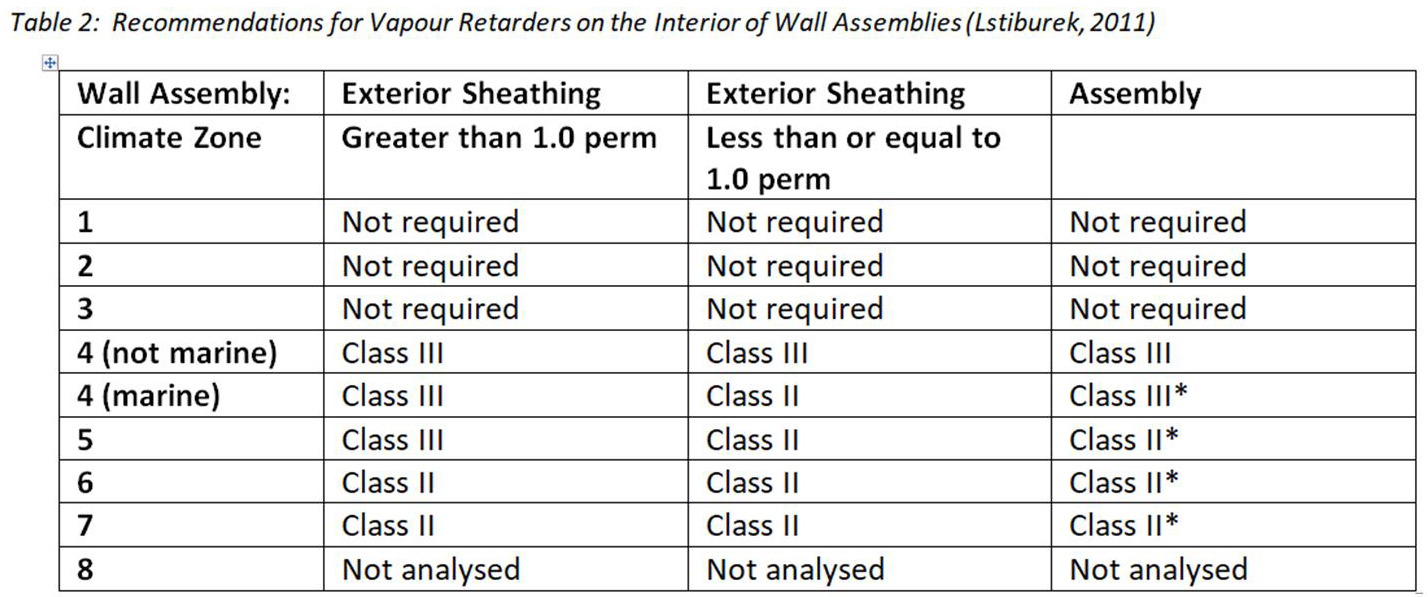

In his categorization of water vapour permeance of various retarders, Joseph Lstiburek continued his analysis with recommendations concerning which climate zones might actually require a vapour retarder, and what type it should be. His recommendations, based on a combination of field experience, laboratory testing, and hygrothermal modeling using WUFI, are presented below in Table 2 (Lstiburek, 2011). Lstiburek’s research pointed out, “In Chicago [climate zone 5, same as Toronto] where plywood or OSB sheathing is used, an unfaced fiberglass batt can be installed within the wall cavity and gypsum board painted with latex paint (Class III vapor retarder) is required on the interior of this assembly. If this assembly is moved to Minneapolis [climate zone 7], a Class II vapor retarder is required on the interior (a kraft paper faced fiberglass batt).” As shown by Lstiburek in Table 2, there is no requirement for a Class I vapour retarder (vapour impermeable barrier). However, a vapour impermeable barrier may be required in climate zone 8 or, as previously discussed, in other special circumstances such as a humid swimming pool room.

*Additionally, the interior surface of the exterior sheathing shall be maintained above the dew point temperature of the interior air.

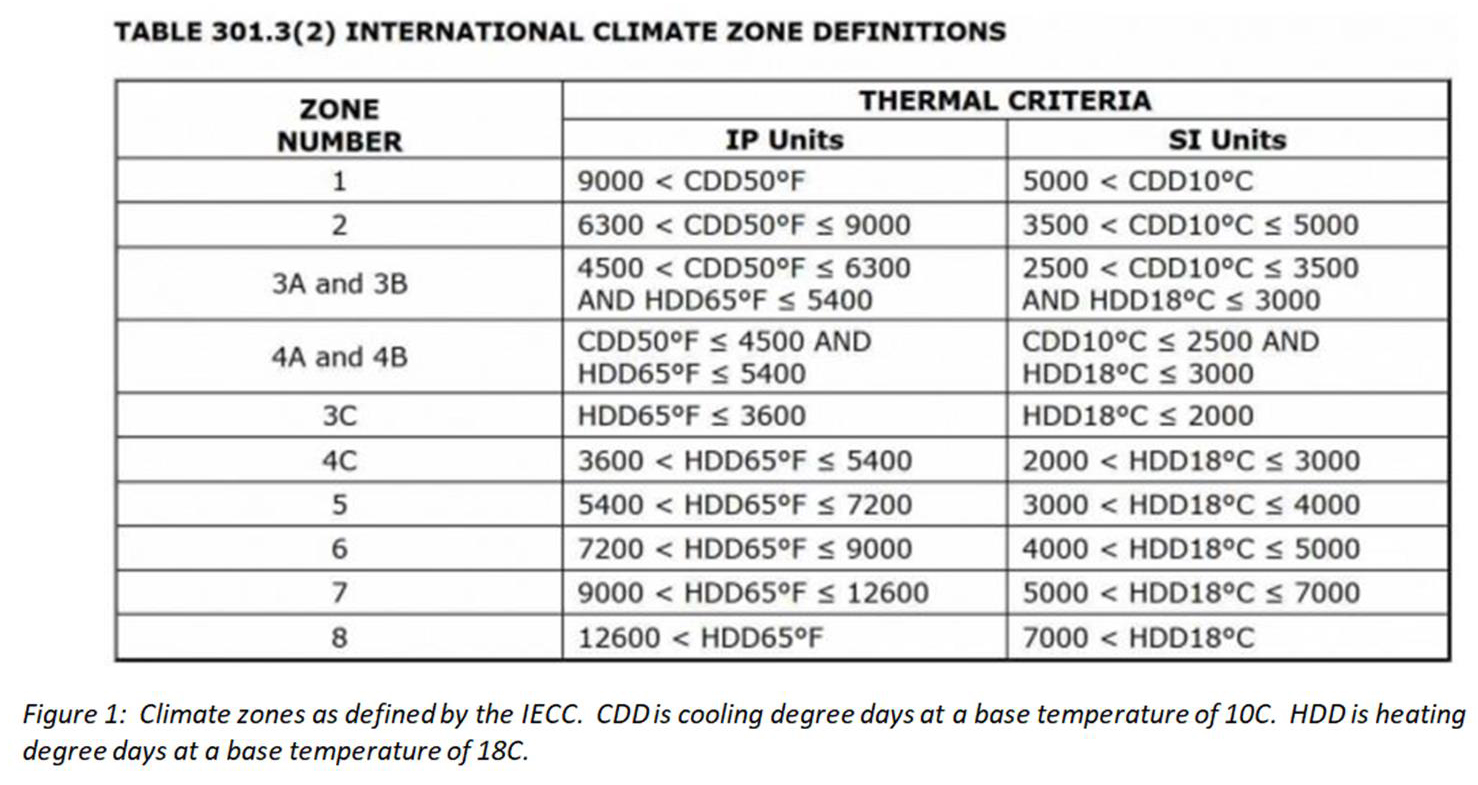

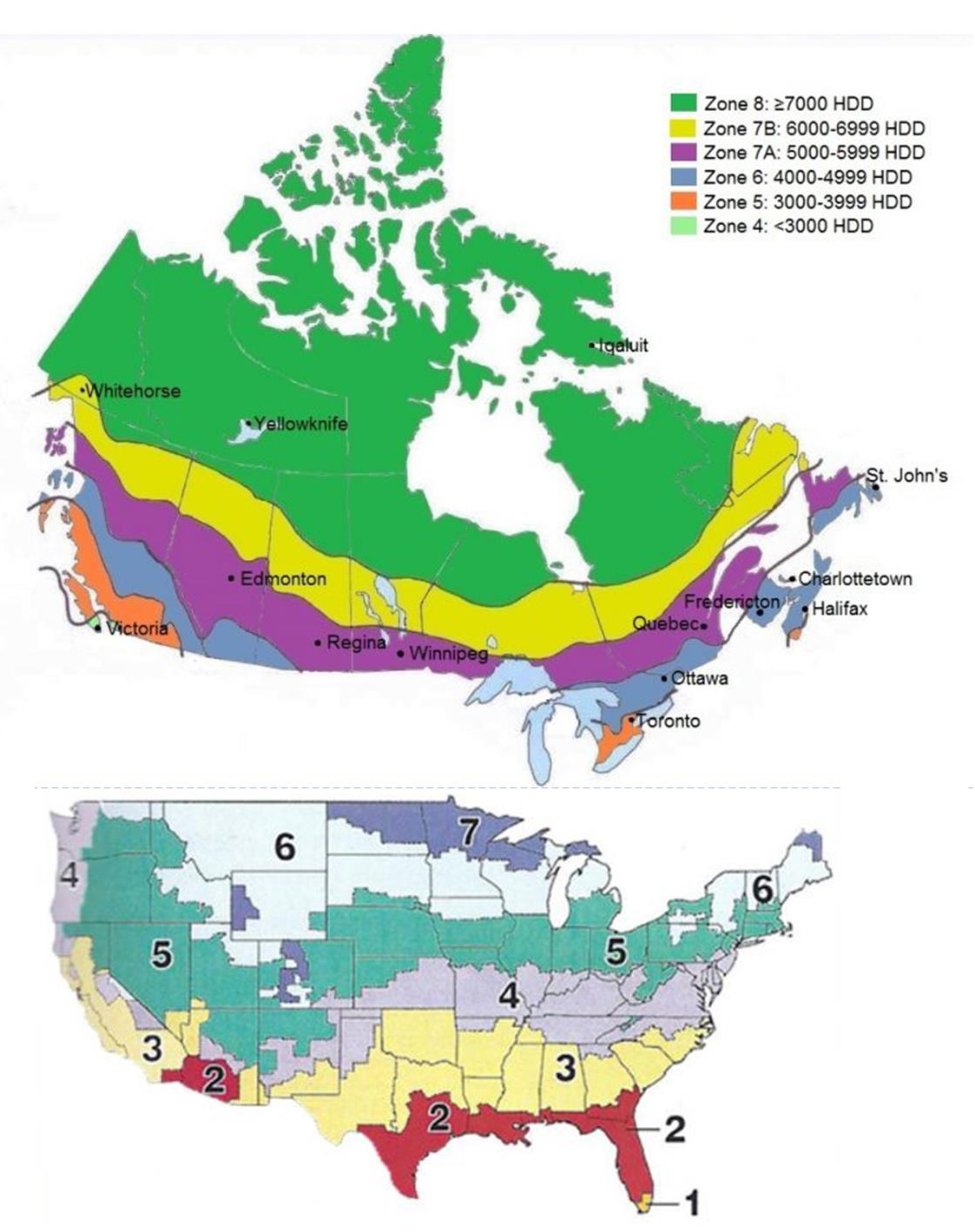

For reference, each climate zone to which Lstiburek referred is defined in Figure 1, can be cross-referenced on a map of Canada in Figure 2 and from the U.S. map in Figure 3. Zones 3 and 4 are divided into A, B, and C representing moist, dry, and marine climates respectively. It can be noted that cooling is the only important factor for zones 1 and 2, heating and cooling for zones 3 and 4, and heating only for zones 5, 6, 7, and 8.

Figure 2 (top): Climate zones on a map of Canada by the National Research Council of Canada. Figure 3 (bottom): Climate zones on a map of the USA by IECC. Alaska, not shown has both climate zones 7 and 8.

An industry resistant to change

In summary, it is critical to understand vapour retarders — their permeability, and where in the building assembly they are needed. As explained, in most cases there is no requirement for a polyethylene vapour impermeable barrier (Class I vapour retarder). In fact, their use as a vapour retarder can be dangerous and should be avoided due to their suffocating drying potential. The assumed requirement for using an impermeable barrier resulted from limited research and technology but has had a large and ever-lasting impact on the building industry.

Most building contractors, and even some building engineers, will say that there must be a poly vapour barrier. This is an excellent example of how resistant the construction industry can be to change. Building specialists have known for years that there are in fact many safer options to building a well-designed building, while satisfying the building code’s call for a Class II vapour retarder (“vapour barrier”), other than a poly sheet. Simply put, understanding vapour flow and the permeability of materials is critical for long term building durability.

Grant Walkin (M.Sc., P.Eng) is a building envelope and structural glass engineer at Entuitive Corp. in Toronto that specializes in commercial, institutional, and residential high performance buildings.

Grant Walkin (M.Sc., P.Eng) is a building envelope and structural glass engineer at Entuitive Corp. in Toronto that specializes in commercial, institutional, and residential high performance buildings.

References

Building Science Corporation. (2015, April 24). Info-500: Building Materials Property Table. Retrieved from Building Science Corporation: https://buildingscience.com/documents/information-sheets/building-materials-property-table

Lstiburek, J. (2011, April 15). BSD-106: Understanding Vapour Barriers. Retrieved from Building Science Corporation: https://buildingscience.com/documents/digests/bsd-106-understanding-vapor-barriers

Read Parts One & Two of Grant’s series on building envelopes

Part One: Air sealing is king

Part Two: Do buildings need to breathe?

Advertisement

Print this page

Thank you so much for this information. As an air/moisture barrier based contractor this can dramatically improve the performance of building systems for future developments. It makes sense especially with fluid/liquid applied air/moisture barriers on the cold side of the cavity.

I notice in table two there is an * for zones 4 to 7 noting the need for the dew point of the backside of the exterior sheathing to be above the dew point. This can only be achieved with addition of exterior insulation. So where do theses zones fall for interior VB requirements when they do not have exterior insulation? Vary important information that is not given and not really clear unless people notice the * and even if they do there is no other information on this point.

I would like to contact Grant by email.

Is this possible?

If so please respond via email thank you