Regina Gadacz

Field Tested: DRICORE Subfloor

Renovation ContractorIt's one of the best products I've used for time saving. The total floorspace was approximately 1,400 sq. ft. and I had the whole thing done in about three hours.

by Mark Britnell

The 2′ x 2′ DRICORE tongue-in-groove subflooring panels lock together without any glue or taping of the seams. The underside acts as a physical barrier preventing moisture from wicking up from the concrete foundation into the finished flooring, as well as a thermal barrier to stop the cold from radiating up through the floor. This air-gap technology also allows any water vapour that does wick up through the concrete slab to evaporate, and the thermal break also helps the floor feel warmer.

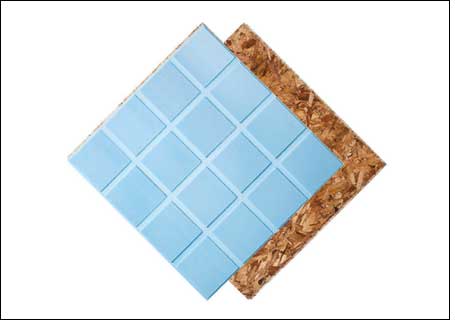

Once installed, the subflooring can be covered with any flooring material your client desires, from carpet and laminates, to tile or engineered hardwood. You can also install radiant heating systems directly on top of DRICORE and, for storage areas, simply seal the surface with polyurethane. DRICORE is durable enough to support the load from home gyms, pianos, and even pool tables. There are two options of subfloor to choose from, original and R+. Both have a top layer of solid OSB. The regular panels have a highdensity plastic bottom, are ¾” high, and have an R-value of 1.44. The Subfloor R+ panels are 1″-high, with a closed-cell extruded foam bottom, boosting the R-value to 3. The plastic panels weigh 6.9 lbs. each, the foam-based ones are 5.2 lbs., and both come with a 25-year limited warranty.

|

|

First Impressions

You know how they say it’s the cobbler’s kids who go shoeless. Well, as most contractors can relate, our basement was long overdue for a renovation. I wanted the finished result to be as cozy as possible so I opted for the DRICORE R+ with the insulated foam bottom.

Before I started, I went online to a watch a few of the instructional videos showing how to install it.

|

|

Right off the bat I knew that the relatively lightweight 2′ x 2′ panels were going to be a lot easier to work with than trying to fight with 4′ x 8′ sheets of plywood. I’m not even sure I would have been able to get those down the stairs. Plus, there’s less awkward cutting of large sheets to fit around interior walls and other obstacles.

I also like the channels in the bottom that allow for ventilation and an air barrier, and the fact that the tongue-and-groove system gives you a continuous floor.

|

|

Jobsite Experience

It’s one of the best products I’ve used for time saving. The total floorspace was approximately 1,400 sq. ft. and I had the whole thing done in about three hours.

It’s so much easier and quicker to install than the method I was used to, laying down a waterproof membrane, anchoring that down with 2″ x 2″ pressure-treated wood, filling in rigid insulation between the PT, and then covering it all with plywood. And you don’t have a drainage system that way. Installing DRICORE is pretty much idiot proof: even a DIY homeowner could do it.

|

|

Measure the floorspace first to figure out if you have to rip the first row before you start. You want a minimum width of 3″ of panel along the perimeter walls. I used a standard wood blade on my tablesaw, but you could even cut the panels with a circ saw. You just have to be careful when cutting that you don’t accidently cut off the tongue side when you need to insert that into the groove.

Once your first piece is in, you just use a piece of 2×4 or even an offcut to tap the pieces together. There’s no gluing required or seams to tape. There are even levelling shims available if your floor is uneven. Another thing to keep in mind is that you want to stagger the seams. So if you start your first row with a whole panel, rip one in half to start the second row.

In order to install an old-style, waterproofed and insulated subfloor correctly, the price is comparable. But labour time is way down so it’s beneficial for the client and myself to invest in DRICORE. Time is money after all.

Before and after installation, I decided to test out the temperature difference. The subfloor raised the temperature of the floor by 3°C.

Since installing DRICORE in my own home, I’ve already used their subfloor on two projects for clients. In fact, when I’m quoting on new basement renovations, I refuse to take on projects without using it.

|