John Bleasby

New ways to build with blocks

Canadian ContractorTechnology pushes self-insulated and lightweight alternatives to concrete to new levels

A poured concrete or concrete block foundation wall combined with stick frame construction above grade may still be the favored way to build most homes in Canada, but alternative ideas are being brought forward to deal with higher insulation requirements and to reduce construction time. Let’s have a look at a couple of the latest concepts.

Polystyrene concrete blocks

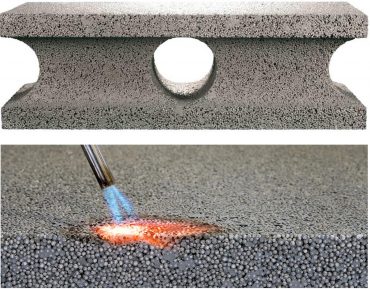

These over-sized blocks from Apex Block, based in Klamath Falls, OR, are made from a mix of cement silica aggregate, recycled polystyrene granules and modifying agents like setting accelerators. Since they are lighter than traditional concrete, construction time is reduced as is worker fatigue. From an environmental standpoint, the recycled polystyrene both adds to the insulation value and keeps polystyrene out of the landfill. The use of fly ash in the concrete mix is also an environment plus, since fly ash is a captured by-product of thermal power stations.

Apex Block claims an R35 insulation value with its new lightweight building block system

Apex claims their product not only earns valuable LEED points by reducing energy costs by 50 percent over traditional building methods but also, “provides protection against flood, fire, high winds, earthquakes and infestation.” The manufacturer says their Keystone Interlocking System eliminates the time and cost of expensive bracing and connection methods associated with the ICF assembly process, thereby simplifying construction and eliminating specialized braces. However, on-line discussions express concern with the porous nature of the block and how water wicking need to be addressed.

The Apex Block product is available nationwide at Lowe’s in the U.S. In conversation with Canadian Contractor, Apex president Dale Siens said that Canadian distribution, through Lowes Canada and/or through area distributors, will be announced shortly, along with a number of new innovative building products based on their proprietary technology. As for cost comparisons to traditional methods, the company presents a chart on their website suggesting an 1800 square foot building space could be built in 30 per cent less time with Apex Block versus a 2 x 6 framed structure at a cost premium of approximately 12 per cent.

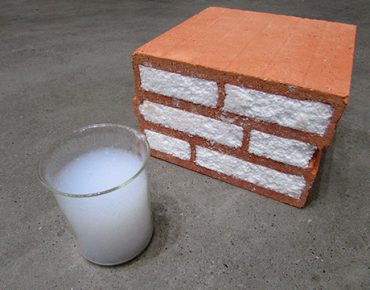

Bautech Systems claims their block system is highly resistant to fire and storms

More variations on the theme

Bautex Systems of San Marcos, TX, offers a number of system-oriented structural solutions that can be used for homes as well as multi-story buildings. Of particular interest in the Bautex Block, a patented composite block using expanded polystyene(EPS) for lightweight and high insulation values, and cement for durability and fire resistance. The company claims that exterior walls built with Bautex Block result in buildings that are constructed faster, have significant energy efficiency cost savings, are quieter and healthier, have no exterior air and moisture problems, and are highly resistant to storms and fire.

Omni Block of Las Vegas, NV, offers a patented insulated cementitious masonry unit (CMU) wall system which, according to the company, “combines the benefits of indigenous aggregates, expanded polystyrene foam insulation, thermal lag (the delay, disruption and redirection of heat flow), exposed thermal mass on the interior side which allows the absorption of heat and air tightness” that results in high R-values and overall thermal performance. In essence, it is evolved form trandstional cinder blocks filled with molded EPF inserts. This makes it easy for builders to adapt, since assembly is much the sam as before. The poroduct is manufactured using, “safe, clean, non-toxic, and non-polluting processes,” and by-products of oil refinery waste and abundant inorganic elements locally sourced and quarried. The company claims that in terms of cost, “Omni Block is the most cost efficient and competitive insulated building material available.” The company website offer a cost estimate and comparison chart.

The Aeroblock, under development by of Swiss Federal Laboratories for Materials Science and Technology , uses a space-aged gel that delivers incredible strength and insulation qualities that delivers many times the performance of standard hollow blocks

Turning ICF’s inside out

Scientists at the Empa group of Swiss Federal Laboratories for Materials Science and Technology have been working on a new insulated brick using an insulating material called Aerogel. They claim a wall constructed from Aerobricks conducts heat up to eight times better than one made from standard clay and shale bricks.

The Empa group claims a regular brick wall would need to have a depth of more than 6 feet to provide the same insulating properties as an 8-inch deep Aerobrick wall. One made from perlite bricks would need to be about 35 percent thicker than an Aerobrick wall with the same insulating properties.

Aerobricks are made from hollowed standard clay. The key is the Aerogel foam material that fills the hollows and bonds with the brick. You could realistically call it ‘space-aged’. — NASA uses the material to insulate spacesuits. Aerogel is a lightweight, material made from a gel in which gas replaces the gel’s otherwise liquid component. The tiny bubbles minimize the movement of the air molecules through the material. Aerogel absorbs almost no moisture, making it an air and vapor barrier preventing moisture passing from the wall exterior into the building’s interior.

The downside is cost. It is estimated that using Aerogel would add $550 to every three-square feet of wall. Wider use and volume manufacturing would hopefully bring this premium down. However, there is the issue of thermal bridging — Thermal conductivity would pass from the exterior to the interior via the clay brick material itself due to absence of any apparent thermal breaks.

When it comes to improving wall construction and energy-efficiency benefits, the residential construction industry can look forward to a wave of new innovations to come.

Got feedback? Make your opinion count by using the comment section below,

or by sending an email to:

JBleasby@canadiancontractor.ca

Follow John on Instagram and on Twitter for notifications about his latest posts

![]()

This is very interesting John. Several products here that are new to me; even if I am not sure that they are ideal for our work, am always keen to see what is new to the market and/or coming domestically.

Here is another similar product (for above grade walls only, in particular for sound or fire separation) that is already available in Canada and in fact developed/manufactured in Cambridge, ON: a mortarless, aerated concrete, interlocking block http://litebuilt.ca/liteblok/